We are happy to announce that our team has developed the KrakenBox – an autonomous error detector for industrial Cyber-Physical Systems (CPS). It is based on an LSTM deployed on a small Jetson Xavier. The KrakenBox was tested and demonstrated on a Simulink model of two robotic manipulators extended with an error injection interface. More details below in the text and our video.

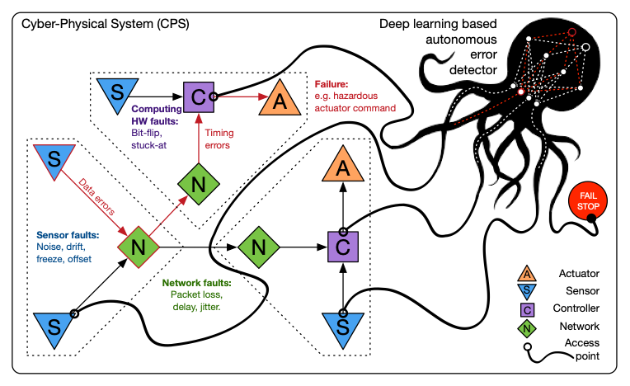

DL-based error detection: Error detection is a well-known concept applied in a broad range of areas, including systems engineering, where it helps to detect errors and prevent failures. During the runtime, an error detector identifies whether a failure will occur in the future, based on the assessment of current and previous system states. Error detectors are fed with time-series data that comes from different system components. Traditional model-based and signal processing based error detectors are successfully employed for Fault Detection and Isolation (FDI) in mechatronic systems. Modern Cyber-Physical Systems (CPS) are considerably more complex both from structural and behavioral points of view. They consist of sensors, microcontrollers, networks, and actuators that interact with each other, generate a substantial amount of data, and form extremely complex system operational profiles. These heterogeneous components are subject to specific errors, e.g., spikes, off-sets, or delays, that may result in system failures. The application of traditional error detection methods requires expert knowledge and manual tuning. As the complexity of modern systems increases, it becomes more and more challenging to apply traditional FDI. Deep Learning (DL) techniques in terms of training a classifier (a Deep Neural Network) to distinguish between normal and abnormal system behavior have been found as promising candidates for on-line error detection. Scalable deep learning-based methods surpass traditional ones in terms of performance as the data size increases.

DemoSystem: For the sake of flexibility, we experimented with a Simulink model of two industrial robotic manipulators. The robots imitate an industrial process. The Simulink model is extended with UDP blocks that stream sensor signals of the DemoSystem to our KrakenBox. The DemoSystem UI allows the user to control the DemoSystem and inject different types of errors, either in manual or automated (random) modes. The error injection is based on the FIBlock, also developed by our team.

The FIBlock is a powerful fault injector for Simulink models. This technology is open-source and available in the MathWorks File Exchange.

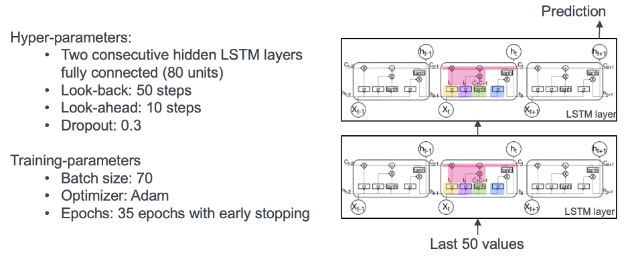

KrakenBox: The error detector itself is deployed on a small DL-purposed NVIDIA computer that can be connected to the DemoSystem either Wirelessly or via Ethernet. We have experimented with various DL-based error detection techniques and neural network architectures. The best performance was achieved using the prediction approach. We use a light-weighted two-layer LSTM-based predictor. The KrakenBox operates either in learning and error detection modes. After the training, the LSTM starts predicting the next signal values. The error detection is achieved via intelligent processing of the residual between predicted and actual signal values. If the residual is higher than a predefined threshold, then KrakneBox alarms about the error. We researched several methods for the automatic definition of the threshold values. The results are present in our recent paper.

Jun.-Prof. Andrey Morozov

This project is supported by Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (BAuA)